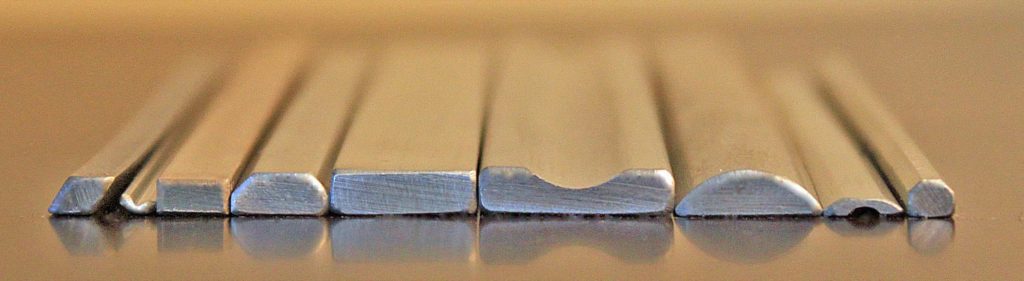

Rolled Shaped Wire products all begin their manufacturing process with a metal round wire starting diameter that is rolled to size and shape through a series of rolls and intermediate anneals, when applicable.

Custom Profiles and Shaped Wire products can lower costs due to the reduction of machining time and material waste as it’s produced near-to or made-to the size and shape needed. It is supplied in continuous coils with fewer or no welds for longer run times, highly accurate shapes, and consistent properties throughout the cross-section of the wire. Shaped wire can be symmetrical or asymmetrical and is available in stainless steel, carbon alloys, red metals, titanium, nickel alloys, and exotic alloys. One common use for shaped wire is ‘wedge wire’ produced specifically for filter screens and liquid-solid separation and used in a wide variety of industries like pulp & paper, waste treatment, fish hatcheries, and commercial walkways. Shaped wire is also used for spring applications, automotive, aerospace, medical, electronics, and more.

Flat wire is generally defined as a dimensional cross-section of less than a 5:1 ratio. It is used for applications where a burr free edge is critical and rolled edge strip is not a viable option due to cross section size or mechanical property requirements. Flat wire is generally offered as a ‘natural round’ edge created by reducing the starting diameter round wire with top and bottom rolls creating a ‘natural’ curvature (round edge) that forms as the top and bottom of the round wire is flattened. Flat wire can also be produced with controlled radius corners or a shaped square edge. These additional edges are formed with side rolls. Flat wire is used for countless applications from Li-Ion batteries, windshield wiper blades, hand tools, guide wires, window mechanisms, springs, and more.

Square wire is another popular wire shape and is used in hundreds of end uses such as header bars, eyeglass frames, orthodontic wire, and hand tools. It is shaped with top, bottom, and side rolls and can be produced with controlled radius edges or a shaped square edge.

Benefits of Shaped Wire over Machined Bar or Plate:

• Continuous coils with fewer or no welds & multiple winding options

• Tight dimensional tolerances

• Produced to finish size or near-finish size for no, or minimal machining

• Consistent properties throughout the cross section of the wire

• Ability to roll complex shapes

• Can be produced to specific mechanical property ranges

Submit your quote for Shaped Wire Products Here or contact Tom Nichols at 800-800-4422 for more information.