Customers often require their material to meet certain metal mechanical properties: tensile strength, yield strength, elongation, and hardness. Our in-house metallurgical expert, Gene Sheldon, explains the meaning behind these four properties (all of which can be found on your Gibbs certificate).

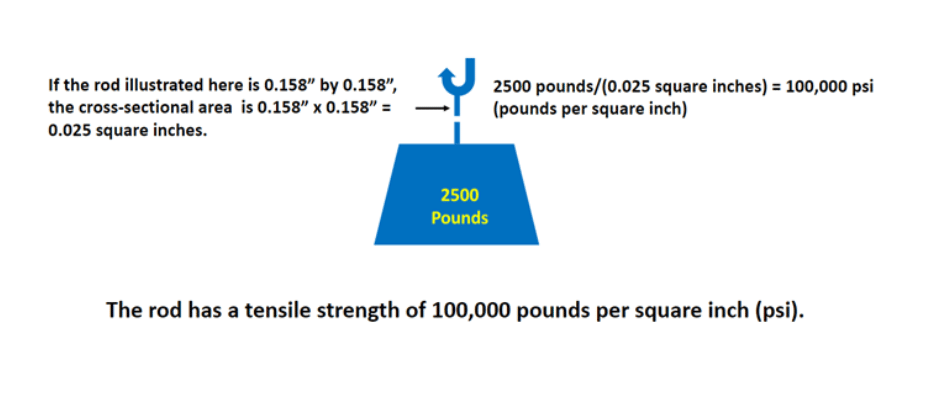

Tensile Strength:

The maximum load the material can bear before it fails. The unit of measure is Stress, which is the applied load divided by the parts cross–sectional area.

The greater the tensile strength the more load the material can bear before it fails.

Occasionally stress is reported in ksi.

- 1000 pounds = 1 kilopound, 100,000 pounds = 100 kilopounds.

- 100,000 pounds per square inch (psi) = 100 kilopounds per square inch i.e., ksi.

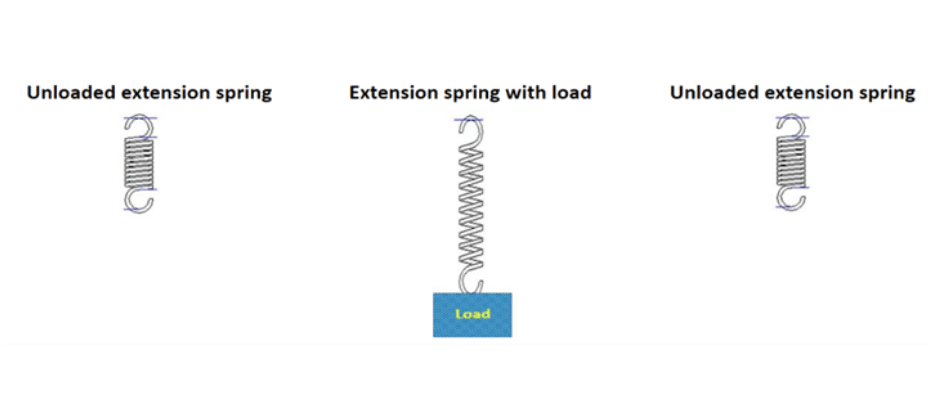

Yield Strength:

The maximum load the material can bear before taking a permanent set. The unit of measure is Stress, which is the applied load divided by the parts cross–sectional area.

When a load is applied to a material it stretches. The greater the load the more the material stretches.

When the load is less than the yield strength, the material returns to its original shape when the load is removed.

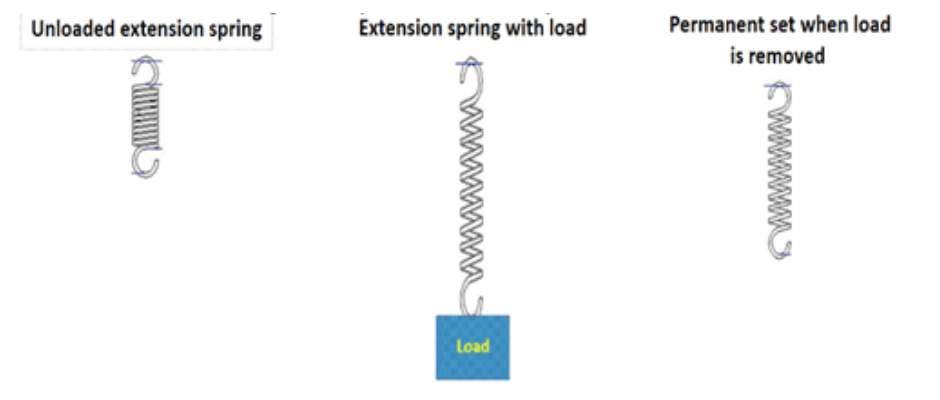

When the load exceeds the yield strength, the material stretches when the load is applied. When the load is removed the material will contract slightly, but it will not go back to its original shape – there will be a permanent set. The greater the yield strength the greater the load can be applied before the material takes a permanent set.

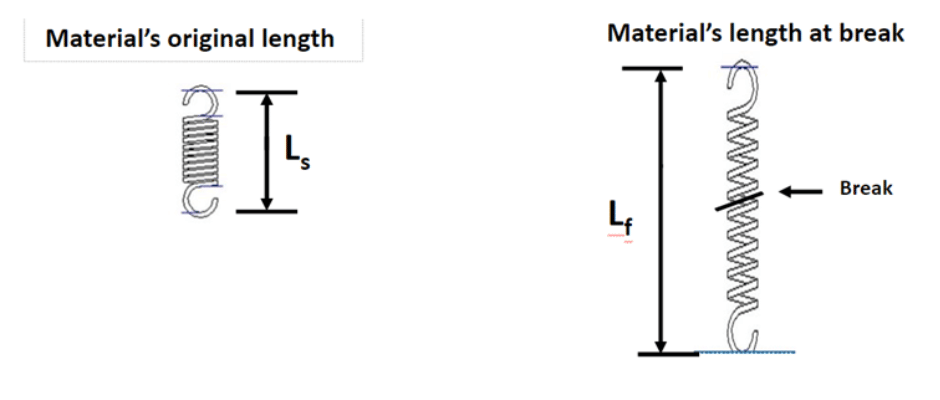

Elongation:

The maximum amount the material can be stretched before it breaks. The unit of measure is % Elongation, which is the ratio of the amount the material stretched when it broke relative to the starting length.

- The calculation is [(Lfinal/Lstart)-1]* 100 = % Elongation

Hardness:

The material’s resistance to indentation. Typically, hardness is reported as a Rockwell number.

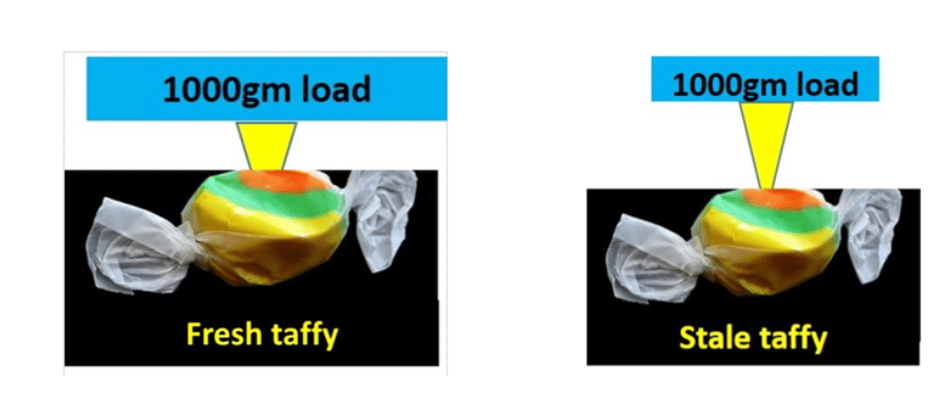

Hardness is determined by placing an indenter on the metal surface, applying a specific load to the indenter, and measuring the depth of the indentation.

- The softer the material the deeper the indentation.

- The hardness values are inversely proportional to the depth of the indentation (the deeper the indentation the lower the hardness value.

- The depth of the indentation in the stale taffy is less than the depth of the indentation in the fresh taffy, indicating the stale taffy is harder than the fresh taffy.

- There is a direct relationship between the hardness and metal strength.

- The harder the material the higher the tensile strength.

- Hardness is typically reported in a number of ways depending on the type of apparatus used.

- Rockwell machines = HRB, HRC

- Vickers machines = HV