The Gibbs Interwire Edge… Better springs and longer lasting parts start with high quality edging!

Edge defects can contribute to lower spring cycle life, fatigue issues, and early part failure. Not all skived edges are equal. Gibbs Interwire understands why the edge matters to the performance of your products and has developed a proprietary process to ensure a superior edge. Gibbs Interwire works diligently to provide a consistent and clean edge in order to prevent stress risers which contribute to lowering the cycle life of the spring.

Highly acclaimed for our ability to provide a superior skived, square, or round edge on material as light as 0.0025”, Gibbs Interwire continually strives to further improve our process. Edging is a combination of art, science, and the right equipment. Our technicians have decades of experience and metal working mastery that, when combined with our meticulously maintained dies and equipment, produce a repeatable and superior high quality edge, on time, every time.

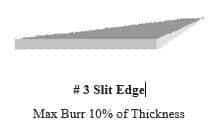

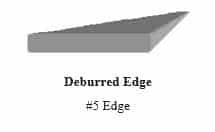

Gibbs Interwire can provide a #1 round edge, # 5 square or deburred edge, in addition to, the standard #3 slit edge.

We are happy to work with customers on special edging requirement